Description

Sampled air then passes through the Iodine Filter Cartridge where the Iodine activity is absorbed. The MCA Type-A detector mounted facing the filter monitors the iodine activity. The whole detector filter set up is housed in a shielding assembly of 100 mm thick lead to minimise the effect of background radiation.

Sampled air then passes through the Gas Chamber of FPNG Monitor of about 2 Liters volume where the FPNG activity is monitored by a Type-A detector mounted facing the chamber. The whole assembly is housed in a shielding assembly of 100 mm thick lead to minimise the effect of background radiation.

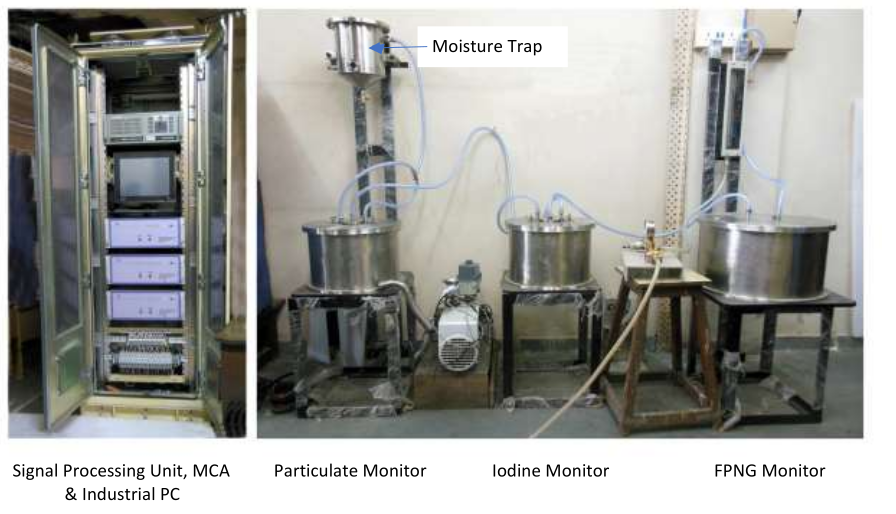

The sampled air after monitoring is retuned back to the stack by means of a vacuum pump. All the MCAs are connected to industrial Ethernet Switch, Industrial Workstation/PC and then to PCIS through Ethernet TCP/IP interface. Analog outputs from industrial Workstation are connected to radiation data Acquisition System. MCA, Signal processing Unit, Ethernet Switch, Industrial Workstation/PC and Isolation Transformer are mounted in a rack of Standard Electronic cabinet.

The system can be connected to Central Clock System for time synchronization. The system can be configured to receive stack flow rate signal for calculating release rate and integral release.

The system is tailored to customer requirement and specifications. A typical installation at a Nuclear Power plant is shown below.