|

|

|

|

|

Industrial Products

|

|

|

|

Broken Bag Indicator, PBI-1 offered by Para Electronics, is suitable for Fluidized

Air Bed Dryers used in Pharma and Chemical Industries.

PBI-1 works on tribo-electric principle. Current pulses generated due to the impact

of powder leak, are sensed by the probe unit mounted in the exhaust duct .These

input pulses are converted in to 4 to 20 mA output. The Readout unit displays the

current value in % on a Bar Graph Display. 4 to 20 mA output and potential free

Alarm Relay Contacts are available for PLC operations.

To avoid false alarms and to detect genuine broken bag, time delayed alarm circuit

is incorporated in the readout unit. Delay time is adjustable between 7 to 70 seconds.

|

|

|

Self diagnostic current input signal is internally fed to the probe to continuously

monitor the reliable functioning of the Broken Bag Indicator. The distance between

the probe unit and readout unit can be as long as 20 to 25 meters.

Specifications :

|

|

|

Read Out Unit

|

|

Input Current

|

:

|

4 to 20 mA as received from Probe Unit

|

|

Display Readout

|

:

|

Bar Graph type Green color LED Indicating input current and set alarm level

|

|

Preset Time

|

:

|

Settable between 6~7 to 60~70 sec (approx)

|

|

Alarm Output

|

:

|

LED indication on front panel Change Over Relay Contacts

|

|

POWER

|

:

|

240V AC Mains, with proper earth

|

|

Probe Unit

|

|

Input Range

|

:

|

0 to 10 nA

|

|

Output Range

|

:

|

4 to 20 mA

|

|

Power Supply

|

:

|

± 12V DC (Internally generated by Readout Unit)

|

|

Connector

|

:

|

Allied type MS 3102R-14S-6P MIL Grade 6 Pin Male Connector

|

|

Probe

|

:

|

SS, 10 mm dia x 250 mm long Suitable for duct sizes of 200, 300, 400 mm dia

|

|

Electronics

|

:

|

Aluminum housing, 95 mm dia x 70 mm long

|

|

Mounting

|

:

|

1” dia Standard NPT threads

|

|

Mechanical

|

|

Dimensions

|

:

|

150 L x 50 D x 100 H mm

|

|

Weight

|

:

|

Approx 1 kg

|

|

Interconnecting Cable

|

:

|

20 meter long

|

|

|

|

Top

|

|

|

|

Para Particle Aerodynamic Size Separator Model PPASS-01 is designed and developed

for measurement of the size distribution in a host of applications such as pollution

and atmospheric studies, inhalation hazard evaluation, characterizing lung delivery

systems, material synthesis, etc. PPASS-01 is based on the principle of inertial

impaction and separates particles according to their aerodynamic diameters in the

range of 0.53 to 10 m in seven class intervals. It has a special feature that it

can be used with the number of stages less than the maximum of seven. PPASS-01 is

manufactured under license from Bhabha Atomic Research Centre, Mumbai. The design/technical

knowhow transferred to Para Electronics- Manufacturing Division of Electronic Enterprises

(India) Pvt. Ltd., is the product of developmental work by Environmental Assessment

Division of BARC.

The PPASS-01 is useful for occupational monitoring of radioactive and non-radioactive

environments, arising in the context of material processing, metal cutting, powder

handling, etc. It is useful for air quality regulators as well as for researchers

engaged in various aspects of air pollution and aerosol research. It can also be

used by the pharmaceutical industries for characterising the lung aerosol delivery

systems such as nebulisers and metered dose inhalers.

|

|

|

Some important features of PPASS-01 are

- higher flow rate of 45 lpm, enabling a quicker collection of samples for analysis

- load any number of stages other than the maximum seven, depending upon the requirement

- new design of collection plates reduces inter-stage losses and ensures uniform particle

deposits

- assembly or disassembly made easy by the use of stud and wing nut arrangement low

internal wall losses

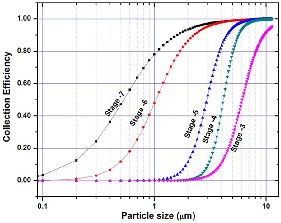

The adjoining graph shows the response functions for the impaction stages of PPASS-01

indicating the collection efficiency variation with particle size. To standardize

cut-off characteristics, a very simple and easy calibration method using well characterized,

nebuliser generated polydisperse aerosols has been evolved. Each unit is tested

for its stage response as per BARC test procedures.

|

|

|

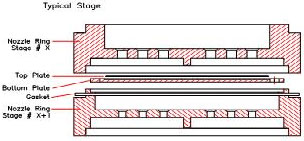

Typical Stage :

A typical stage is shown alongside. Nozzle rings are made of aluminium alloy of

grade 6061, collection and impaction plates are of stainless steel, connecting adapters

and fasteners are of brass. The unit is made leakproof with the use of neoprene

gaskets

A typical stage is shown alongside. Nozzle rings are made of aluminium alloy of

grade 6061, collection and impaction plates are of stainless steel, connecting adapters

and fasteners are of brass. The unit is made leakproof with the use of neoprene

gaskets

|

|

Specifications :

|

|

Impactor Stages

|

:

|

7 Nos

|

|

Operating Flow rate

|

:

|

45 lpm

|

|

Cut-off Diameters

|

:

|

8.95, 7.91, 6.09,4.15, 2.94, 1.03, 0.53 micro meter

|

|

Collection Plate Holder

|

:

|

82 mm Dia

|

|

Collection Substrate

|

:

|

70 mm Dia

|

|

Inlet Cone

|

:

|

25 mm dia

|

|

Unit Dimensions

|

:

|

96 mm Dia x 230 mm Ht

|

|

Weight

|

:

|

2.5 Kg

|

|

Accessories

|

:

|

- Monoblock Dry Vacuum Pump 100 lpm with ¼ hp motor, 230V, 50Hz operation, 1440 rpm,

0-100 lpm Rotameter or Electronic Flow Transducer and Digital Indicatr, Flow Adjust

Bleed Valve

- Carrying Case for PPASS-01 and the pump

|

|

|

|

Top

|

|

|

|

Model PFI -100 is designed for measurement of air flow in the pipes for industrial

applications. It measures air Flow in the range of 0 – 100 LPM. Model PFI-100 works

on 240 V AC Mains Supply. It measures air flow in ½” dia pipe. This air flow is

indicated on 4 x 20 char LCD Display. It also generates 4 to 20 mA output signal,

linearly proportional to air flow in LPM.

Low and High level alarms can be set within the full range of air flow. Air flow

totalizer is also provided to integrate air volume in Liters for the preset time.

Model PFI-100 sensor circuit housed in the probe unit, is a robust, all solid state

device working on Kings law. The length of interconnecting cable between probe unit

and readout unit can be 3 meters long. Necessary ½” pipe couplings are provided

to enable user install the probe in the air line.

|

|

|

Specifications :

|

|

Read Out Unit

|

|

Air Flow Range

|

:

|

0 to 100 LPM

|

|

Accuracy

|

:

|

± 5% of Full Scale

|

|

Menu

|

:

|

4 x 20 Character LCD

|

|

Keyboard

|

:

|

4 keys - TOT, SETUP, ENTER, ESC

|

|

Alarms

|

:

|

Low and High Level

|

|

Alarm Indication

|

:

|

LED on front panel, Relay Contact

|

|

Totalizer Time

|

:

|

Settable up to 24:00 Hrs

|

|

Totaliser On/ OFF

|

:

|

Through Keypad

|

|

Output

|

:

|

4 to 20 mA proportional to LPM

|

|

Operating Voltage

|

:

|

+240V AC, 50 Hz Mains Supply

|

|

Mechanical

|

:

|

Steel Housing, panel mounting type

|

|

Dimensions

|

:

|

140 W x 110 H x 210 D mm

|

|

Output

|

:

|

4 to 20 mA proportional to LPM

|

|

PROBE UNIT

|

|

Probe Construction

|

:

|

Stainless Steel, M14, Threaded female port

|

|

Dimensions

|

:

|

Stainless Steel housing, 80 L x 70 H x 25 D mm

|

|

Output

|

:

|

1~2 meters long, 3 core cable with Amphenol connector

|

|

|

|

Top

|

|

|

|

|

|

Copyright © 2011 Electronic Enterprises (India) Private Limited

|

|

|

|