|

Plating Products

|

|

Destructive Method

In early 80's PARA Electronics added another group of products to cater the Surface

Finishing Industry. Destructive & Non-Destructive Coating/Plating thickness measuring

instruments - GEDET, Delta Meter were introduced first. More additions followed

upon successful acceptance by the Indian Industry. State of Art technology lead

to introduction of microprocessor based 'Smart' Instruments like Smart GEDET, Smart

Step etc. Recently SmartStep is replaced by 'Graphic Step' and SmartGedet is replaced

by 'Graphic Gedet'

|

|

|

|

GEDET is a versatile and sophisticated instrument for measurement of coatings of

metal or alloy on substrates by electroplating or other methods. It is simple enough

to be welcomed by operator of average skill when a large number of routine measurements

on standard metallic coating are to be made. At the same time, it is sophisticated

enough to be employed by a scientist for his investigation purposes on metallic

and alloy coatings. It works on Coulometric principle. It has a very high accuracy

and repeatability. It can measure thickness on flat or curved surfaces. GEDET also

measures coating on known length of wire or pins using Acrylic cell which is supplied

as an accessory.

|

|

|

|

Standard Coating / Base combinations

|

|

COATING

|

BASE

|

|

CADMIUM

|

Aluminium, Brass, Copper, Nickel, Steel

|

|

CHROMIUM

|

Aluminium, Brass, Cadmium, Copper, Nickel, Steel, Stainless Steel

|

|

COPPER

|

Aluminium, Iron, Nickel, Non-metals, Steel

|

|

GOLD

|

Brass, Copper, Nickel

|

|

LEAD

|

Aluminium, Brass, Chromium, Copper, Silver, Steel

|

|

NICKEL

|

Aluminium, Brass, Chromium, Copper, Silver, Steel

|

|

SILVER

|

Brass, Copper, Nickel, Tin

|

|

THIN SILVER

|

Brass, Copper, Nickel, Tin

|

|

TIN

|

Brass, Copper, Nickel, Steel

|

|

TINPLATE

|

Steel

|

|

ZINC

|

Aluminium, Brass, Copper, Nickel, Steel

|

|

|

Alloys: Lead/Tin (40/60), Tin/Zinc (78/22) Tin/Copper diffusion layer. Various Other

Alloy Combinations are also possible

Specifications :

|

|

Measurement range

|

0 to 99.9 microns

|

|

Accuracy

|

+/- 5%

|

|

Readability

|

0.1 micron

|

|

Area of Deplating

|

Approx. 10mm2 Circular with 3.5mm Diameter gasket

|

|

Electrolyte Required

|

Approx. 2cc per measurement

|

|

Power

|

240/120V; 50/60 Hz AC, Single Phase, 12 VA

|

|

Main Frame

|

21W X 28D X 12H cm

|

|

Weight

|

3 Kg. without cell stand/pump unit

|

|

|

Accessories :

|

|

Electrolyte

|

Formulae for different Coating/Base combination provided with instrument.

|

|

Acrylic Cell

|

For thickness of coating on wires and small parts.

|

|

Gasket

|

3.5mm etching diameter.

|

|

|

|

Top

|

|

|

|

SIDET-II is a versatile and sophisticated instrument for measurement of coatings of metals as well as alloys applied on substrate by electroplating or other methods. It fulfils a long standing need on the Indian market for low cost, reliable and accurate coating thickness measuring instrument.

SIDET-II works on coulometric principle. SIDET-II is a microcontroller based system hence it is more flexible in design and need not required any complicated control option, menus, and settings to carry out measurement. It has high accuracy & repeatability . It can measure thickness on thick and flat surfaces.

SIDET-II has unique feature of Plate / Base combination (PBC) plug. Different PBC plugs are supplied for measurement of different plating. Use of pre-tested, imported, 2.5mm dia gasket supplied with SIDET-II ensures accurate result.

|

|

|

|

Standard Coating / Base combinations

|

|

METALLIC COATING

|

BASE METAL / MATERIAL

|

|

CADMIUM

|

Aluminium, Brass, Copper, Nickel, Steel

|

|

CHROMIUM

|

Aluminium, Brass, Cadmium, Copper, Nickel, Steel, Stainless Steel

|

|

COPPER

|

Aluminium, Iron, Nickel, Non-metals, Steel

|

|

LEAD

|

Aluminium, Brass, Copper, Steel

|

|

NICKEL

|

Aluminium, Brass, Chromium, Copper, Steel

|

|

SILVER / THIN SILVER

|

Brass, Copper, Nickel, Tin

|

|

TIN

|

Brass, Copper, Nickel, Tin

|

|

ZINC

|

Aluminium, Brass, Copper, Nickel, Steel

|

|

|

Measurement range

|

0 to 99.9 microns

|

|

Accuracy

|

For 2.5mm Dia Gasket within +/- 0.75 microns for plating up to 15 microns & +/- 7.5% for 15 microns and higher plating

|

|

Readability

|

0.1 micron

|

|

Gasket Diameter

|

2.5 mm

|

|

Area of Deplating

|

Approx. 5mm2 Circular with 2.5mm Diameter gasket

|

|

Electrolyte Required

|

Less than 2cc

|

|

Power

|

240V AC, 50Hz, Single Phase, 12VA

|

|

Main Frame

|

29 L X 25.8 W X 12H cm

|

|

Weight

|

SIDET-II = 2.95Kg

Stand Assembly with wooden block = 2.15 Kg

|

|

Electrolyte

|

Formula for different plate/ base combination provided in manual.

|

|

|

|

Top

|

|

|

|

Smart Sidet is a smart, versatile and sophisticated instrument for measurement of coatings of metals as well as alloys applied on substrate by electroplating or other methods. It fulfills a long standing need on the Indian market for a smart, reliable and accurate coating thickness measuring instrument.

Smart Sidet has facility to store and transfer the results to PC via USB. It also provides various built-in plate / base combinations.

|

|

|

|

Smart Sidet works on Coulometric principle. Smart Sidet is a microcontroller based system hence it is more flexible in design. Menu driven software enables user to select the desired plate / base combination. Once this is selected through Menu, Smart Sidet carries out thickness measurement without manual intervention. It has high accuracy & repeatability. It can measure thickness on thick and flat surfaces as well as plating on wire.

Smart Sidet can be supplied either 3.5 mm dia or 2.5 mm dia or 1.5 mm dia gaskets. User can decide about the gasket diameter depending upon the available flat surface on the plated sample and inform us about his choice of gasket at the time of ordering.

|

|

|

|

Standard Coating / Base combinations

|

|

METALLIC COATING

|

BASE METAL / MATERIAL

|

|

CADMIUM |

Aluminium, Brass, Copper, Nickel, Steel

|

|

CHROMIUM

|

Aluminium, Brass, Copper, Nickel, Steel, Stainless steel

|

|

COPPER

|

Aluminium, Iorn, Nickel, Non-metals, Steel

|

|

LEAD

|

Aluminium, Brass, Copper, Steel

|

|

NICKEL

|

Aluminium, Brass, Chromium, Copper, Steel

|

|

SILVER /THIN SILVER

|

Copper, Brass, Nickel, Tin

|

|

TIN

|

Aluminium, Brass, Copper, Nickel

|

|

ZINC

|

Aluminium, Brass, Copper, Nickel, Steel

|

|

|

Specifications :

|

|

Measurement Range

|

0 to 99.99 microns

|

|

Accuracy

|

For 2.5mm Dia Gasket : +/- 0.75 microns for plating up to 15 microns and +/- 7.5% for 15 microns and higher plating

For 3.5mm Dia Gasket : +/- 0.5 microns for plating up to 15 microns and +/- 5% for 15 microns and higher plating |

|

Readability

|

0.1 micron or 0.01 microns (for thin coatings)

|

|

Gasket Diameter

|

3.5mm or 2.5 mm or 1.5mm (to be specified while ordering)

|

|

Area of Deplating |

Approx. 5mm2 Circular with 2.5 mm Diameter gasket

|

|

Electrolyte Required

|

Approx. 2cc

|

|

Power |

240V AC, 50Hz, Single Phase, 12VA

|

|

Main frame

|

29 L* 25.8 W * 12 H cm

|

|

Weight

|

SMART SIDET = 2.95Kg

Stand Assembly with wooden block = 2.15 Kg

|

|

Electrolyte

|

Formula for different plate/ base combination provided in manual.

|

|

|

|

Top

|

|

|

|

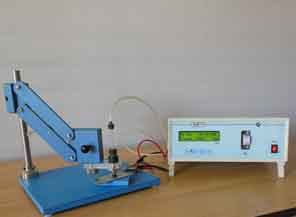

Graphic Step is an advanced version of our earlier Smart Step. It works on

Coulometric Principle. It measures plating thickness of various metallic coatings

on variety of base materials. Step measurement of Duplex and Triplex Nickel is also

possible in this instrument. In Duplex Nickel on Steel / Copper combination, it

measures thickness of bright and semi-bright nickel and measures electrochemical

potential between these two layers. In Triplex Nickel on Steel / Copper combination,

instrument measures the thickness of bright nickel, active layer and semi-bright

nickel and measures electrochemical potential between two layers. Graphic Gedet

is similar to Graphic Step except can not perform Step Measurement

|

|

|

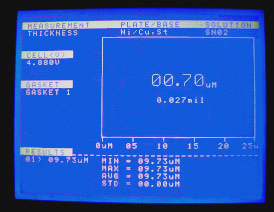

Graphic Gedet Mode: Thickness Measurement

More than 20 plate/base combinations can be tested on Graphic Step. Combinations

are listed on next page. Instrument is very easy to operate. It has a setup mode

to select the plate—base combination. Using UP/Down/Scroll keys, required plate-base

combination can be selected. After selection, instrument goes into measurement mode.

Air agitation is necessary to maintain proper electrochemical contact and to maintain

constant rate of de-plating. After setting up the sample, just press the Start key.

Measurement will start.

More than 20 plate/base combinations can be tested on Graphic Step. Combinations

are listed on next page. Instrument is very easy to operate. It has a setup mode

to select the plate—base combination. Using UP/Down/Scroll keys, required plate-base

combination can be selected. After selection, instrument goes into measurement mode.

Air agitation is necessary to maintain proper electrochemical contact and to maintain

constant rate of de-plating. After setting up the sample, just press the Start key.

Measurement will start.

No further adjustment of any kind is necessary. Constant current passes through

the cell and etching takes place. Instrument stops automatically whenever base material

is reached. During measurement cycle, instrument displays the thickness in microns

as well as mils. Also displays the cell voltage. Operator can selectively store

the reading which can be used for generating statistical information. Statistics

like MIN, MAX, AVG and Standard Deviation will be done automatically and displayed

on LCD screen.

|

|

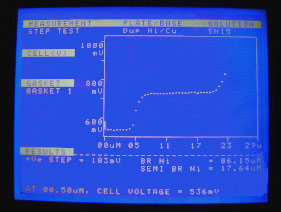

Graphic Step : Duplex / Triplex Step Measurement

Instrument goes into Step measurement mode whenever the user selects Duplex / Triplex

Nickel plate - base combination. In Step measurement, setup the sample. Use reference

electrode and SN-15 electrolytic solution for measurement of electrochemical potential

between two layers. Press Start key to start measurement. Instrument shows graph

of electrochemical potential versus thickness on LCD screen. Typical graph for Duplex

Nickel is shown in the picture. Instrument passes constant current through cell

and etching starts. First the bright Nickel layer gets removed. Then etching of

the semi-bright nickel layer starts. Cell voltage rises at this time. Rise in cell

voltage can be observed on LCD screen. After etching of semi-bright layer, base

material is exposed to the solution. At this point, cell voltage rises for copper

or drops for steel base material. Instrument detects this change and stops automatically.

Step change in voltage is calculated automatically. Also the thickness of bright

and semi-bright nickel layer is calculated and displayed on screen. For Triplex

nickel layer, instrument measures the thickness of bright nickel, active layer and

semi-bright nickel and measures electrochemical potential between two layers.

Instrument goes into Step measurement mode whenever the user selects Duplex / Triplex

Nickel plate - base combination. In Step measurement, setup the sample. Use reference

electrode and SN-15 electrolytic solution for measurement of electrochemical potential

between two layers. Press Start key to start measurement. Instrument shows graph

of electrochemical potential versus thickness on LCD screen. Typical graph for Duplex

Nickel is shown in the picture. Instrument passes constant current through cell

and etching starts. First the bright Nickel layer gets removed. Then etching of

the semi-bright nickel layer starts. Cell voltage rises at this time. Rise in cell

voltage can be observed on LCD screen. After etching of semi-bright layer, base

material is exposed to the solution. At this point, cell voltage rises for copper

or drops for steel base material. Instrument detects this change and stops automatically.

Step change in voltage is calculated automatically. Also the thickness of bright

and semi-bright nickel layer is calculated and displayed on screen. For Triplex

nickel layer, instrument measures the thickness of bright nickel, active layer and

semi-bright nickel and measures electrochemical potential between two layers.

|

|

Precautions :

Silver/Silver Chloride Electrode and the Gasket are the key components in step measurement.

Periodic reconditioning of electrode is necessary for accurate measurement. Instrument

has a facility to recondition the electrode. Care should taken while handing the

rubber gasket. SS cell should be cleaned after every measurement. Conditioning of

Silver/Silver Chloride Electrode, cleaning of cell and gasket and proper setup of

sample will lead to successful step measurement.

|

|

Software :

|

|

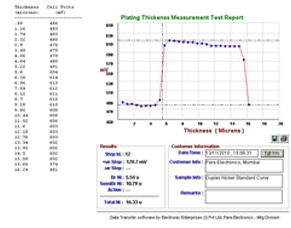

Graphic Step stores data in a non-volatile memory. Even after switching off the

instrument, the data array is preserved. Data can be transferred to PC via USB port.

Data retrieval software will be supplied for data storage and transfer. All the

calculations for determination of step(s) or layer thickness are done automatically

at the end of the measurement. Instrument determines the points (thresholds) at

which change in layer takes place. Due to non-uniform coating, sometimes the instrument

may show wrong results. In such cases, transfer the data to PC and run the software.

In the software, user can change the thresholds by looking at the graph displayed

on screen. This helps to get the proper and more accurate results.

|

|

|

|

Standard Coating / Base combinations

|

|

Metallic Coating

|

Base Metal / Material

|

|

CADMIUM

|

Nickel, Steel

|

|

CHROMIUM

|

Nickel, Steel, Brass, Copper

|

|

COPPER

|

Aluminium, Steel, Nickel, Zinc, ABS

|

|

LEAD

|

Aluminium, Copper

|

|

NICKEL / ELECTROLESS NICKEL /

DUPLEX / TRIPLEX NICKEL

|

Copper, Steel

|

|

SILVER / THIN SILVER

|

Brass, Copper, Steel

|

|

TIN

|

Brass, Copper, Nickel, Tin

|

|

ZINC

|

Aluminium, Copper, Nickel, Steel

|

|

BRASS

|

Steel

|

|

LEAD + ZINC ALLOY

|

Steel

|

|

TIN + ZINC ALLOY

|

Steel

|

|

|

Specifications :

|

|

Supply Voltage

|

:

|

110/230 Volts , 50/60 Hz AC

|

|

Display

|

:

|

320 x 240 pixel Graphic LCD

|

|

Keypad

|

:

|

8 Keys pad for solution set up, measurement & data transfer

|

|

Gasket Diameter

|

:

|

1.5mm / 3.5 mm

|

|

Accuracy

|

:

|

Better than +/- 7% for thickness measurement

0.1 microns for thick coatings, 0.01 microns for thin coatings

|

|

Area of Deplating

|

:

|

Approx. 10mm2 Circular with 3.5 mm Diameter gasket

|

|

Electrolyte Required

|

:

|

Less than 2cc / measurement

|

|

Air Agitation

|

:

|

Built-in, Bellow driven air pump

|

|

Stand Assembly

|

:

|

For setting up the sample & air agitation

|

|

Data Transfer to PC

|

:

|

Through USB port

|

|

Dimensions

|

:

|

29 L x 20 D x 15 H cm

|

|

Weight

|

:

|

GStep / GGedet Unit = 1 Kg

Stand Assembly with wooden block = 2.15 Kg

|

|

Note : We can supply Graphic Step with only Thickness Measurement mode. Step measurement

mode will not be available. Please consult factory for details.

|

|

|

|

Top

|

|

|

|

- Acrylic Cell for use with GEDET, SIDET, GRAPHIC GEDET is most convenient to measure

thickness on wires, small parts, etc.

- Thickness Standards for calibration: Copper, Nickel, Tin on Steel or Copper base.

- Customized semi-automatic Stand is suitable for measurements on outer and inner

surfaces of cylindrical parts such as shells.

- Manual version of the semi-automatic Stand described above is also available.

|

|

|

|

Top

|

|

|